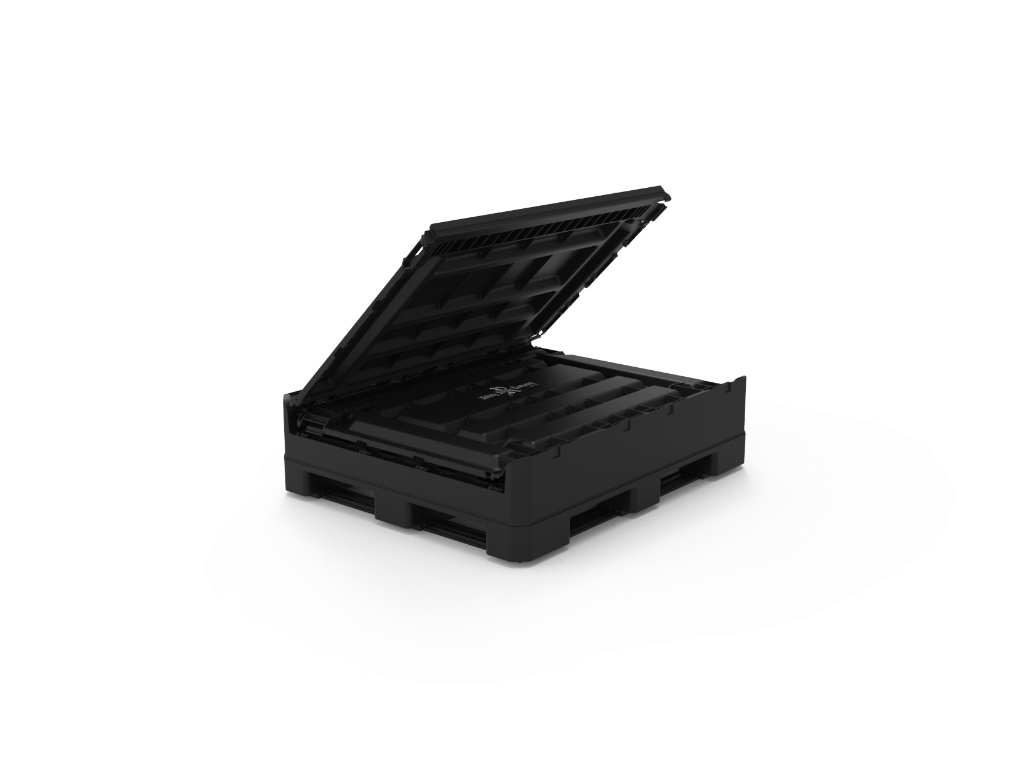

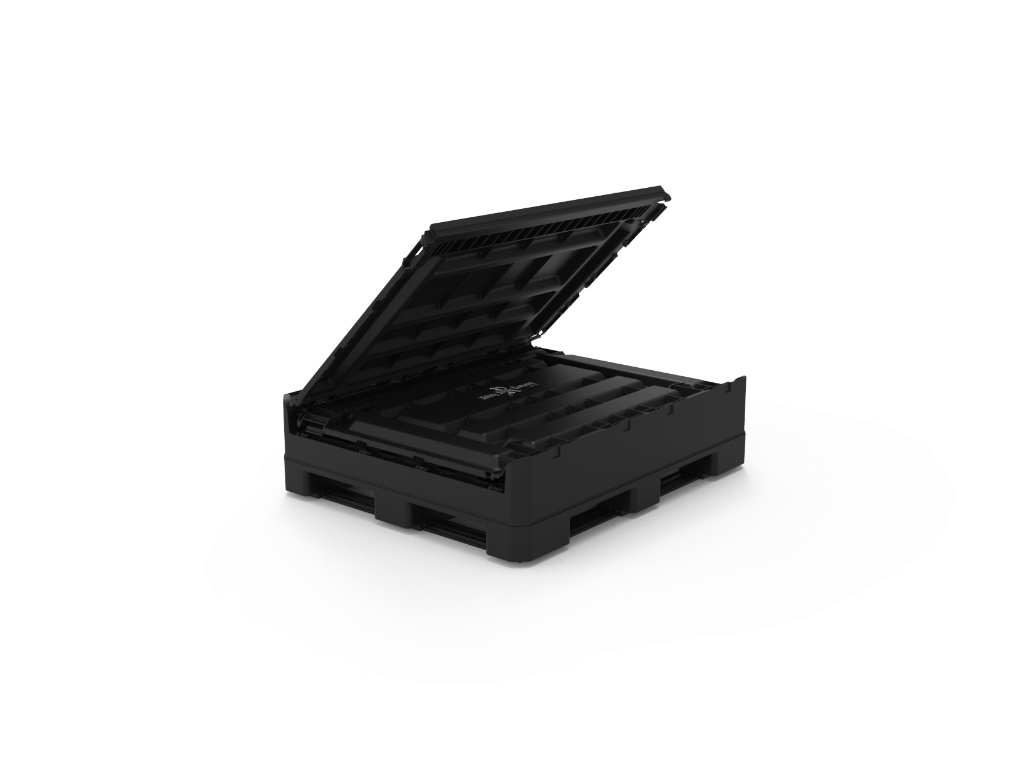

40 x 48 Flex Bin

The 40 x 48 FlexBin by Rehrig Pacific is the ultimate solution for efficient and durable material handling, designed to meet the demanding needs of various industries, including protein and food-grade applications. With advanced materials, innovative design, and enhanced functionality, this bin ensures superior performance and safety.

STD/V/DROP

| Specifications | IN/LB | MM/KG |

|---|---|---|

| Length (L) | 48 | 1,219 |

| Width (W) | 40 | 1,016 |

| Height (H) | 46 | 1,168 |

| Overall Fork Pocket Width (W1) | 30 | 762 |

| Individual Fork Pocket Width (W2) | 12 | 305 |

| Overall Fork Pocket Length (L1) | 32 | 813 |

| Individual Fork Pocket Length (L2) | 13 | 330 |

| Fork Pocket Height (H1) | 4 | 89 |

| Folded Height (H2) | 24 | 610 |

| Nest Increment | 12 | 292 |

| Weight | 102 | 46 |

| Load Capacity | 2,000 | 909 |

| Static Load Rating | 7,200 | 3,273 |

| Dynamic Load Rating | 4,000 | 1,818 |

| 53' Trailer Quantity | 270 | |

HALF HEIGHT

| Specifications | IN/LB | MM/KG |

|---|---|---|

| Length (L) | 48 | 1,219 |

| Width (W) | 40 | 1,016 |

| Height (H) | 26 | 660 |

| Overall Fork Pocket Width (W1) | 30 | 762 |

| Individual Fork Pocket Width (W2) | 12 | 305 |

| Overall Fork Pocket Length (L1) | 32 | 813 |

| Individual Fork Pocket Length (L2) | 13 | 330 |

| Fork Pocket Height (H1) | 4 | 89 |

| Folded Height (H2) | 24 | 610 |

| Nest Increment | 12 | 292 |

| Weight | 78 | 35 |

| Load Capacity | 2,000 | 909 |

| Static Load Rating | 7,200 | 3,273 |

| Dynamic Load Rating | 4,000 | 1,818 |

| 53' Trailer Quantity | 270 | |

| Decoration Areas | WIDTH (IN) | HEIGHT (IN) |

|---|---|---|

| Branding (A) | 10.25 | 6.25 |

| MIL (B) | 4 | 2.75 |

Features & Benefits

• High-pressure injection molding allows a lighter yet stronger part with superior durability compared to other molding methods

• Smooth Walls with minimal to no crevices to allow for easy cleanability

• Advanced copolymer polypropylene, with enhanced impact compared to other materials commonly in use, won't absorb moisture, harmful bacteria, or pathogens

• Full picture frame and cruciform bottom support full edge racking and ensure the pallet works smoothly with conveying and automated pallet handling equipment

• Integrally molded into the side wall, the one-piece latch eliminates costly repairs and spare parts

• Lighter weight than comparable bins, which allows for 2 additional bins per outbound shipment before "weighing out"

• Shares common industry dimensions, allowing it to stack and nest with comparable plastic bins

• Bins stack securely with greater integrity, with or without the optional lid

• Walls fold down and take up less space during empty shipping and storage than comparable bins, which allows for 12% more bins per backhaul

Options

• Various Wall configurations - Standard, V Channel Opening, Drop Wall, and Half Height Options

• Various Runner Configurations available.

• Various colors available

• Hot-stamped logos available for customer-specific branding

• RFID-enabled technology and barcodes available for asset tracking, visibility, and retention via Rehrig Pacific's software